Southern Minnesota Beet Sugar Cooperative has developed the health and safety policy to ensure an injury-free workplace, to communicate our strong commitment to safety and to drive sustainability. Our goal is to establish best practices that exceed regulatory standards and protect all employees with the expectation of zero-lost time incidents.

We are dedicated to fostering a culture of awareness, open communication, education, supervision, and safe working methods.

We devote resources necessary to promote a safe and healthy workplace.

We support and resource the Safety Committee to be a beneficial driver of safety.

We provide training for employees and supervisors that increases their ability to perform their job safely.

We continue to manage and improve systems to identify and remove hazards and plan for foreseeable emergencies.

We ensure all employees comply with health and safety policies.

Our Safety Committee is comprised of employees from management and union, multiple shifts and departments throughout the facility to represent a broad perspective of ideas and issues. The SMBSC Safety Committee is responsible for performing inspections and audits of the facility and making recommendations for changes. Furthermore, the team serves as a conduit for employees to voice concerns in a method that drives response.

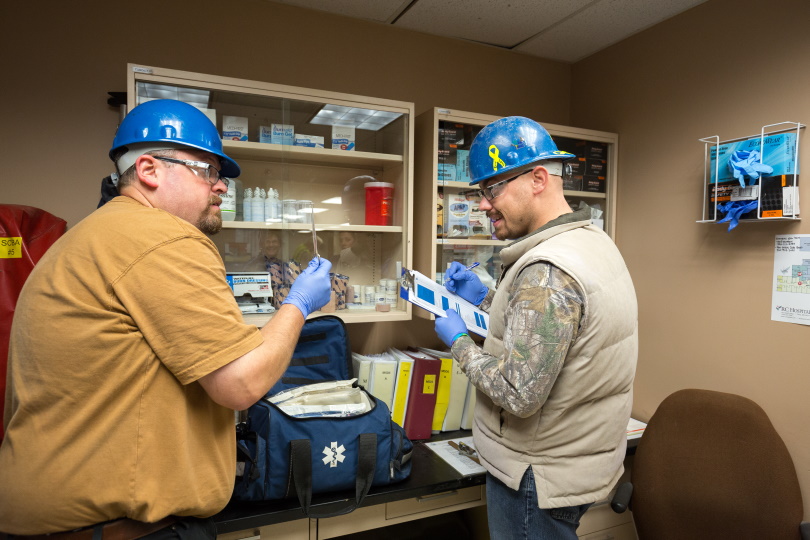

One of the many safety programs at SMBSC includes our Code Blue First Aid Responder program. We have an established team of over 50 employees who are Minnesota Board Certified First Aid Responders. SMBSC conducts annual, on-site training to maintain certifications for these employees.

Preparing for crisis and emergencies is an important step in ensuring a safe work environment. SMBSC has a comprehensive Crisis Management Plan and will continue to refine the plan through regular review and practice drills. We hold fire and severe weather training drills annually. We pride ourselves in our strong relationship with local emergency response teams.

SMBSC considers no aspect of its operation or administration more important than the health and safety of its employees, contractors and visitors.

Safety is the responsibility of every employee with everyone participating in activities to ensure a safe work environment.

Maintaining a safe work environment is a top priority. Each employee is responsible for consistently following all safety procedures, for promptly reporting potential hazards, and foster a proactive culture focused on safe behaviors.

SMBSC employees are trained in the applicable health and safety rules, procedures and hazards for their specific duties. Our training touches our employees regularly though weekly safety discussions, monthly and yearly training sessions, and through new hire orientations.

The Ag staff leads safety year around associated with research, communications, and harvest. Each year SMBSC works with over 500 shareholders and approximately 400 seasonal employees to harvest the approximately 119,302 acres sugarbeets. We drive safety through continuous communications, seasonal safety coordinators and detailed orientation.

SMBSC has implemented a reliability centered maintenance program that uses rigorous preventative and predictive methodologies to significantly improve equipment reliability. This effort focuses on increasing planned work and decreasing unplanned (reactive) work. Planned work is much safer for those employees executing the work, thereby, reducing the number of injuries associated with maintenance activities.